- 您现在的位置:买卖IC网 > Sheet目录251 > SFSD4096L1BN2TO-I-Q2-141-STD (Swissbit NA Inc)FLASH SECURE DGTL CARD SDHC 4G

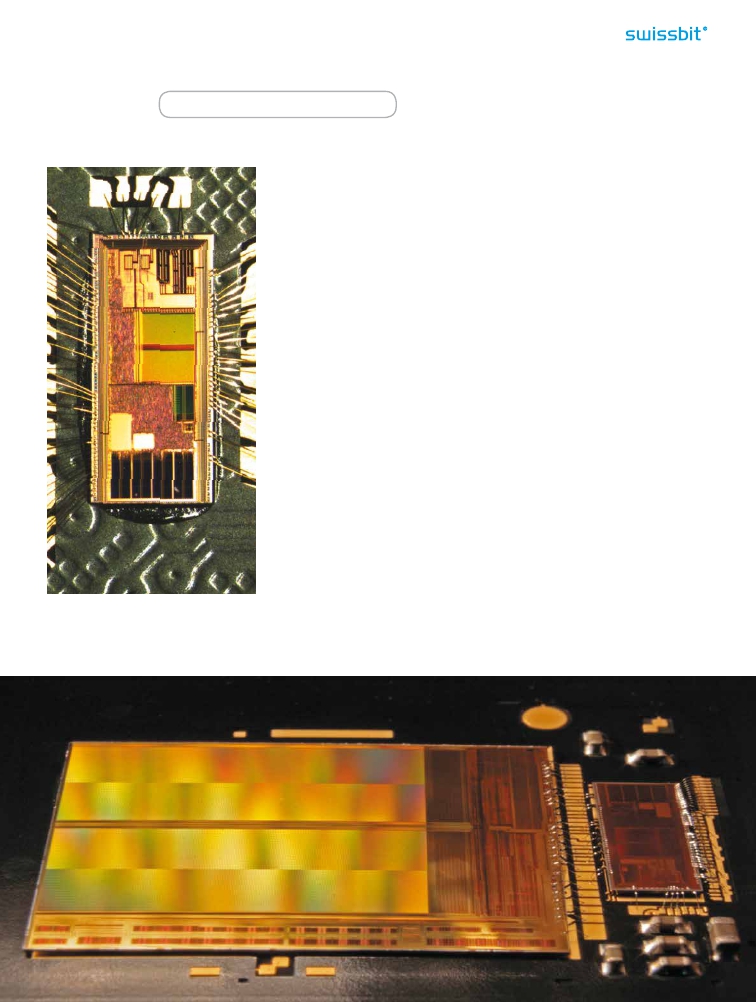

SYSTEM IN PACKAGE (SIP)

System in Package (SiP) is the processing of sensitive bare dies or chips into

robust finished modules or components. With 20 years of experience, Swissbit

successfully uses advanced packaging technologies in order to achieve the

smallest form factors built into Multi-Chip-Packages. With this microelec-

tronic integration approach our products provide more functionality and

highest memory densities inside one package. Various functional blocks

(RF, digital, sensors, security and memory) can be combined, as well as

passive components in a single package.

Beginning with the wafer and bare die handling, Swissbit utilizes a flexible

chip on board (COB) assembly and packaging line. Processes like SMT assem-

bly, die bonding, Au and Al wire bonding, glob top dispensing, under fill,

molding, precise singulation with laser technology, housing, labeling,

laser marking, tampon printing etc. are very well established.

Swissbit has extensive expertise in die stacking and the integration of addi-

tional hardware features, especially for Flash and DRAM devices. An internal

Memory-In-Package line positions Swissbit as a development and production

partner for dedicated or customized memory based products that have

challenging integration and reliability requirements. If customers require

additional resources for designs that have special space or performance

demands, Swissbit has experienced teams of design, test, and quality

engineers along with project managers to provide feasibility studies or

manage entire development projects. In-house prototype, small, and mid-size

assembly lines allow volumes up to 50,000 pieces per month. Swissbit will

provide support from the inception of a project, through design phase,

prototyping, circuit layout and material selection, to providing the proper

packaging for storage and transport.

TECHNOLOGY COMPETENCE

29

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

SFSD8192N1BW1MT-E-QG-111-STD

FLASH MICRO SD 8GB EXT TEMP

SFUI4096J1BP2TO-I-DT-211-STD

FLASH DRIVE USB MODULE U-110 4G

SGN08G64B3BB2SA-CCWRT

SDRAM DDR3 8GB 204 SO-DIMM

SGN08G72G1BB2SA-CCWRT

SDRAM DDR3 8GB 204 SO-UDIMM

SGP1200-12G

FRONT END AC/DC 1133W 12V

SL05.TCT

TVS ARRAY DATA INTFC SOT-23

SL24T1G

TVS LO CAP 300W 24V ESD SOT23

SLD10U-022-B

DIODE TVS AXIAL HI-POWER

相关代理商/技术参数

SFSD4096L1BN2TO-I-Q2-151-STD

功能描述:FLASH SECURE DGTL CARD SD 4G RoHS:是 类别:存储卡,模块 >> 存储器,PC 卡 系列:S-220 标准包装:30 系列:- 存储容量:8GB 存储器类型:存储卡 - Extreme III SD?

SFSD4096L2BM1TO-I-GE-2A1-STD

功能描述:Memory Card SDHC? 4GB Class 6 MLC 制造商:swissbit na inc. 系列:S-45 零件状态:有效 存储器类型:SDHC? 存储容量:4GB 速度:6 类 技术:MLC 工作温度:-25°C ~ 85°C 标准包装:50

SFSD4096L3BM1TO-I-GE-2B1-STD

功能描述:Memory Card SDHC? 4GB Class 10, UHS Class 1 MLC 制造商:swissbit 系列:S-45 零件状态:在售 存储器类型:SDHC? 存储容量:4GB 速度:10 类,UHS 1 类 技术:MLC 工作温度:-40°C ~ 85°C 标准包装:50

SFSD4096L3BM1TO-I-GE-2CP-STD

功能描述:MEM CARD SDHC 4GB CLASS 10 PSLC 制造商:swissbit 系列:S-46 零件状态:在售 存储器类型:SDHC? 存储容量:4GB 速度:10 类,UHS 1 类 技术:pSLC 工作温度:-40°C ~ 85°C 标准包装:1

SFSD4096N1BM1MT-I-DF-221-STD

功能描述:Memory Card microSDHC? 4GB Class 10, UHS Class 1 SLC 制造商:swissbit na inc. 系列:S-450u 零件状态:有效 存储器类型:microSDHC? 存储容量:4GB 速度:10 类,UHS 1 类 技术:SLC 工作温度:-40°C ~ 85°C 标准包装:120

SFSD4096N1BM1TO-I-GE-111-STD

功能描述:Memory Card microSDHC? 4GB Class 6 MLC 制造商:swissbit na inc. 系列:S-40u 零件状态:过期 存储器类型:microSDHC? 存储容量:4GB 速度:6 类 技术:MLC 工作温度:-40°C ~ 85°C 标准包装:64

SFSD4096N1BW1MTEDF111

制造商:Swissbit 功能描述:

SFSD4096N1BW1MT-E-DF-111

制造商:Swissbit 功能描述: